When it comes to creating precision metal parts, CNC machining vs fabrication is a common comparison. While these two manufacturing methods might seem similar, they serve very different purposes – and choosing the right one can make the difference between a flawless final product and costly revisions.

At Megatech, we specialize in bringing complex concepts to life. That often means helping our customers decide whether machining, fabrication, or a combination of both is the best approach for their project.

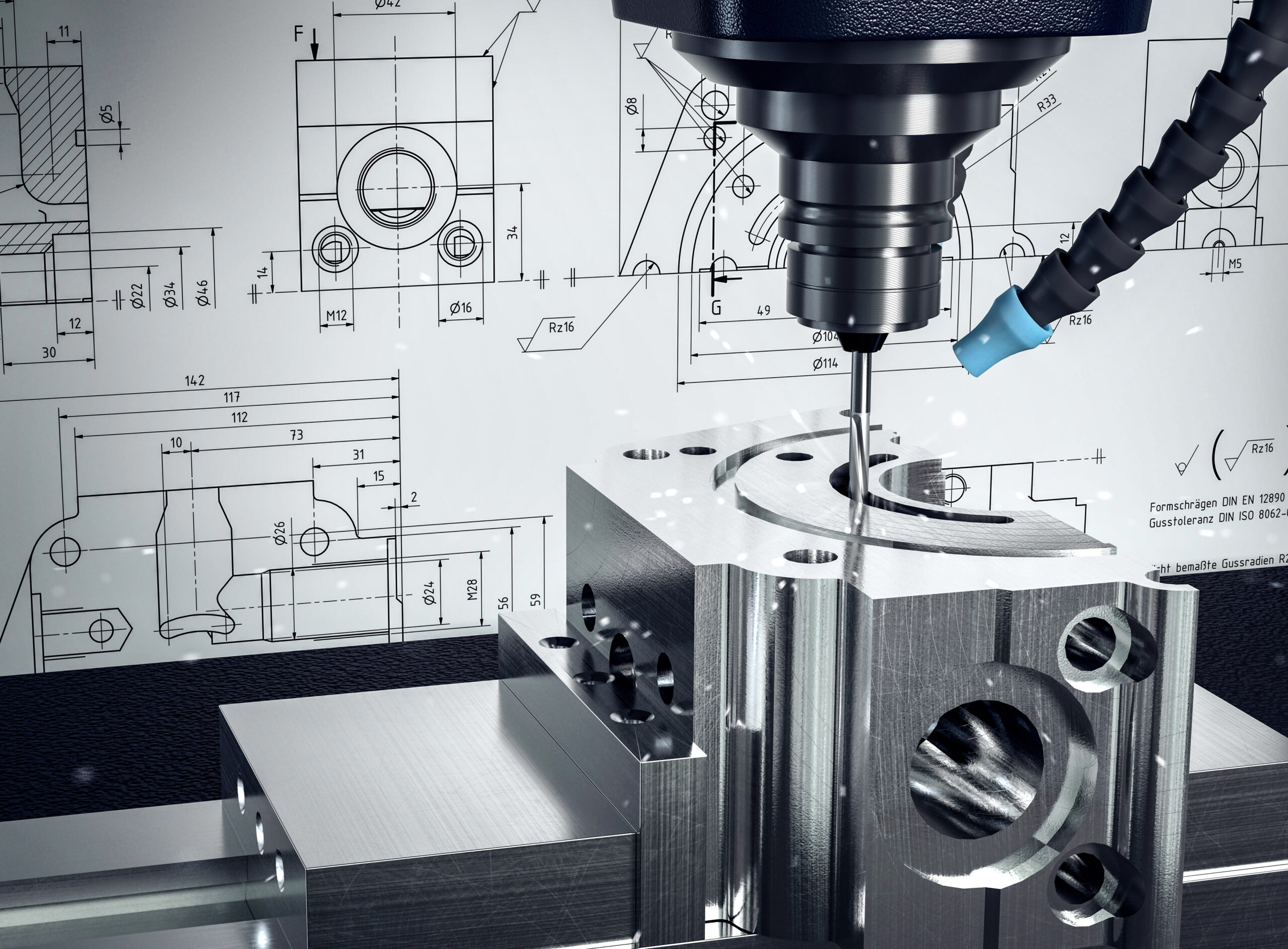

What is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process, where material is carefully removed to create the final part. Using computer-controlled machines and specialized cutting tools, CNC machining delivers:

- Extremely tight tolerances

- Complex geometries that are impossible by hand

- Repeatability for consistent production runs

- High-quality prototypes that match production standards

This makes CNC machining ideal for industries where precision is critical, such as aerospace, defense, robotics, optomechanics, medical devices, and clean energy.

What is Metal Fabrication?

Fabrication focuses on forming, joining, and shaping metal rather than cutting it away. It often involves:

- Laser cutting

- Sheet metal bending

- Welding

- Stamping and punching

Fabrication is ideal for creating structural components or enclosures like brackets, housings, frames, and assembled parts. It provides strength and form, making it perfect for larger elements that don’t require ultra-tight tolerances.

How They Work Together

CNC machining and fabrication are not competing processes – they often complement one another. A project may begin with CNC machining to produce highly detailed, precise components. Those parts might then be combined with fabricated housings or frames to create a complete assembly.

By offering both capabilities under one roof, Megatech helps customers streamline production, reduce lead times, and ensure perfect compatibility between parts. This integrated approach means fewer suppliers to manage and a smoother path from concept to completion.

Making the Right Choice

Determining which process to use depends on your design, timeline, and budget. If your part requires extremely tight tolerances and intricate detail, CNC machining is likely the right fit. If you need larger, structural pieces or assemblies, fabrication may be the better choice.

In many cases, a combination of both delivers the best result. Our team works closely with customers to evaluate each project and recommend the most efficient and cost-effective path forward.

The Bottom Line

CNC machining and fabrication are both essential to modern manufacturing:

- CNC machining delivers unmatched precision and detail.

- Fabrication provides structure and scalability.

- Together, they create complete solutions for complex, high-performance products.

If you’re unsure which process fits your project, our experts are here to help. Contact Megatech to bring your concept from design to delivery with precision and care.

Contact us HERE.

Follow us on LinkedIn HERE.