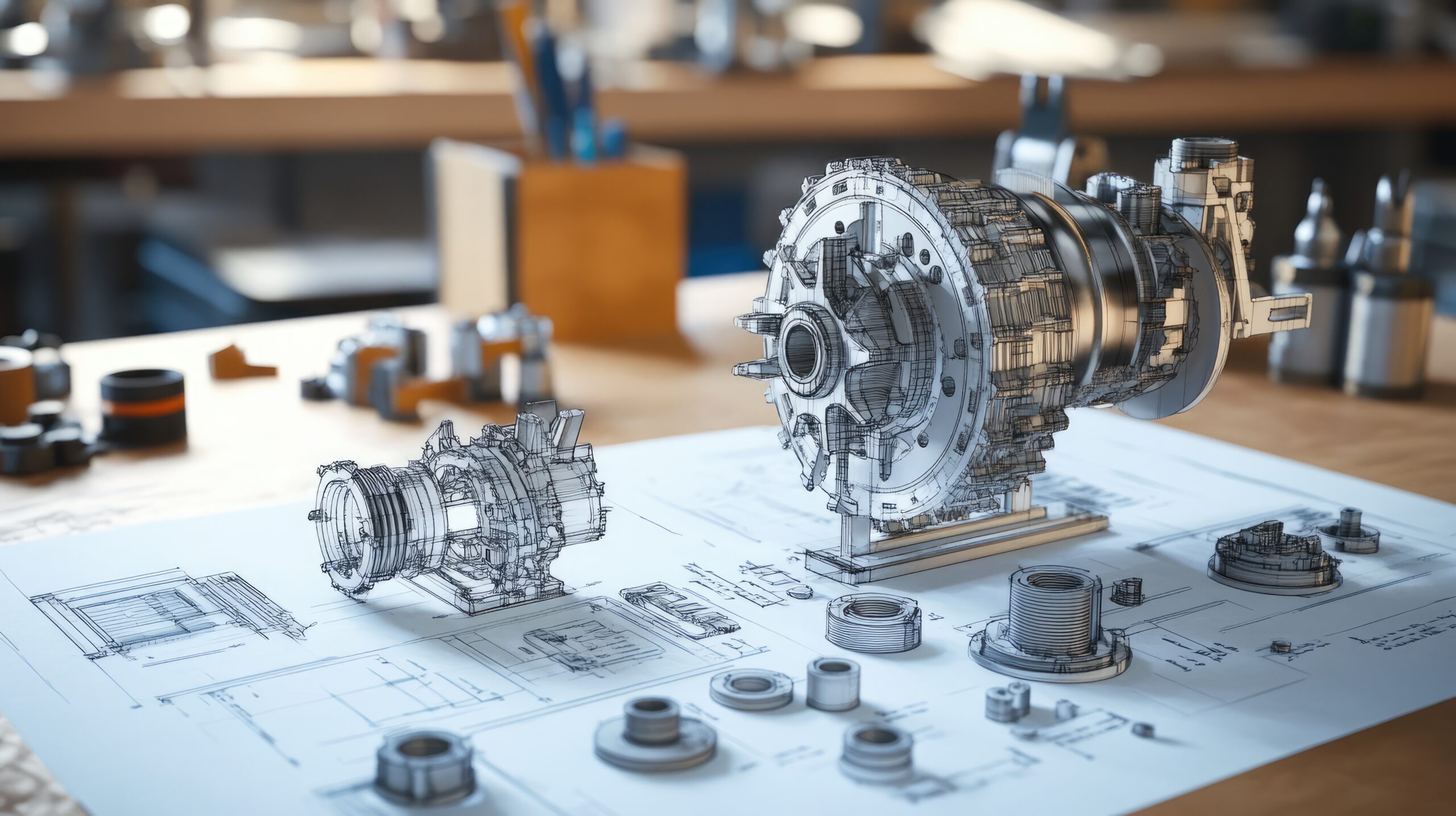

In manufacturing, the term prototype can mean different things to different people. For some, it’s a visual model meant to convey shape and aesthetics. For others, like us, it’s a production-intent, functional part that can withstand real-world conditions.

At Megatech, we don’t do “mockups.” We build mission-ready prototypes.

Visual Models: When They’re Useful and When They’re Not

A visual model (sometimes called a cosmetic prototype or mockup) is designed to show what a product will look like, not how it will perform.

- Purpose: Marketing presentations, investor pitches, design approval.

- Characteristics: Often made from low-cost materials; not built to tolerance or to withstand functional testing.

- Limitations: Cannot validate performance, fit, or manufacturability.

These models have their place, particularly in early concept stages or for stakeholder alignment but they fall short when it comes to actual engineering validation.

Real Prototypes: Built for the Real World

A true prototype is production-representative: made from the actual materials, using the same manufacturing methods, and held to the same tolerances you’d expect in the final product.

- Purpose: Functional testing, fit checks, regulatory compliance, pre-production approval.

- Characteristics: Uses real toolpaths, real materials, and realistic manufacturing workflows.

- Advantages: Identifies design issues early, validates performance under real conditions, and reduces risk in full-scale production.

Why the Difference Matters

When teams rely only on mockups, they risk discovering problems after production begins when changes are far more costly and time-consuming. A mission-ready prototype, on the other hand:

- Confirms the design can be manufactured efficiently.

- Ensures that tolerances and material behaviors are correct.

- Provides accurate data for refining production processes.

In industries like aerospace, defense, medical, and energy, “good enough for looks” is not good enough for safety or performance.

The Megatech Approach

We deliver production-level prototypes from day one:

- Real Materials: Aerospace-grade metals, engineered polymers, and other production-intent substrates.

- Real Processes: The same high-precision machining, inspection, and quality control you’d expect in final production.

- Real Results: Parts that can be tested, validated, and trusted.

Our philosophy is simple: if you’re going to prototype, make it real. Anything less is just a placeholder.

Visual models have their role but when the stakes are high, they’re not enough. By investing in production-representative prototypes early, you save time, reduce costs, and go to market with confidence.

Contact us HERE.

Follow us on LinkedIn HERE.