Blog

Learn more about our process, including the latest blogs and news from MegaTech

2025 in Review: High-Precision Machining Trends That Shaped the Year

As 2025 comes to a close, manufacturers and engineering teams navigated a year shaped by increasing complexity, tighter tolerances, and evolving technical demands. Many of the high-precision machining trends that emerged reinforced the importance of experience, collaboration, and disciplined execution. At Megatech, these trends highlighted a growing need for partners who can support complex, high-accuracy […]

Why Production-Representative Prototyping Matters

In early-stage product development, speed is often the priority. But production-representative prototyping focuses on something just as important: ensuring designs are validated under real manufacturing conditions before moving toward production. At Megatech, production-representative prototyping helps teams reduce risk, improve scalability, and make more informed decisions early in the development cycle. Prototypes Should Do More Than […]

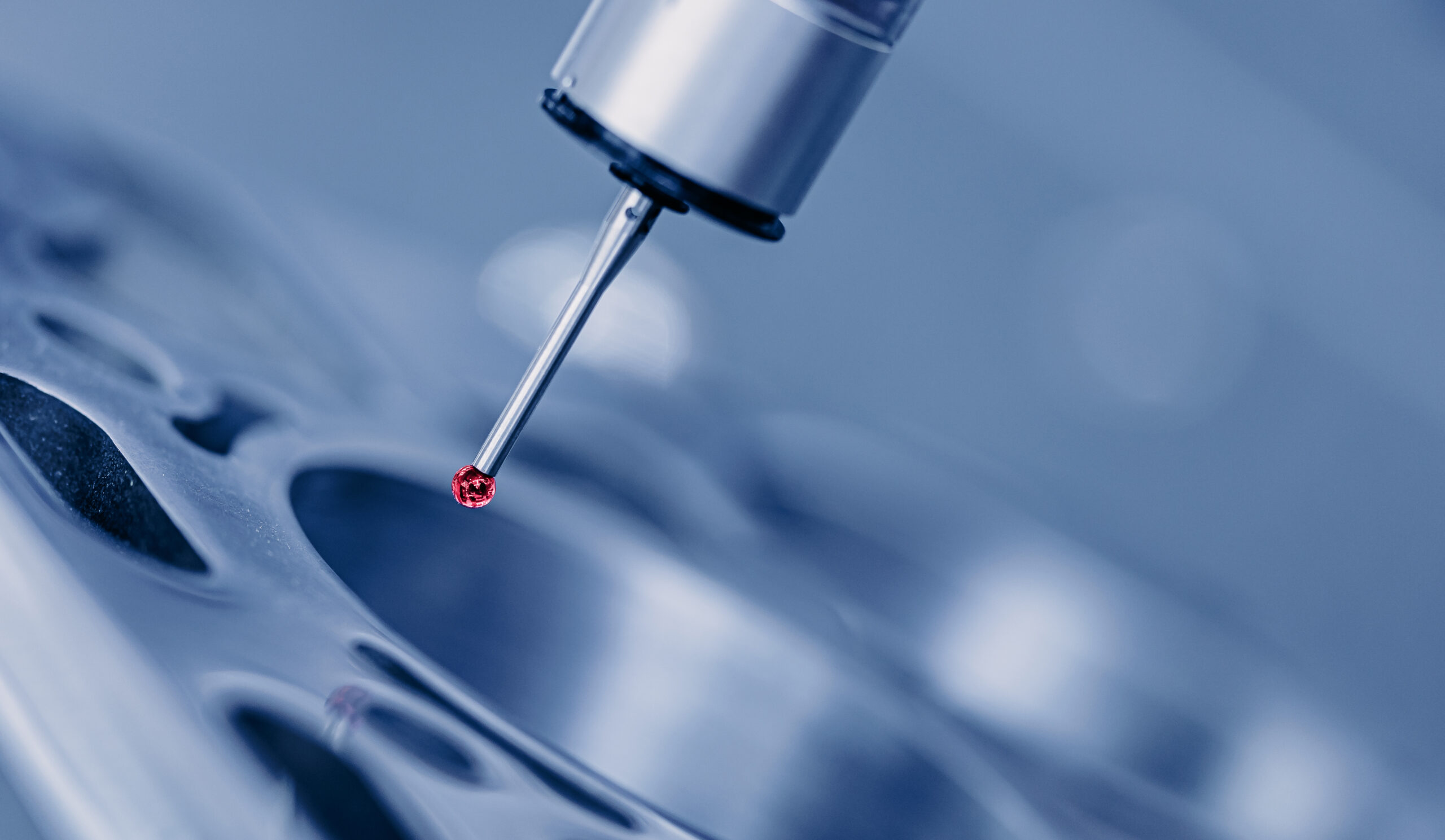

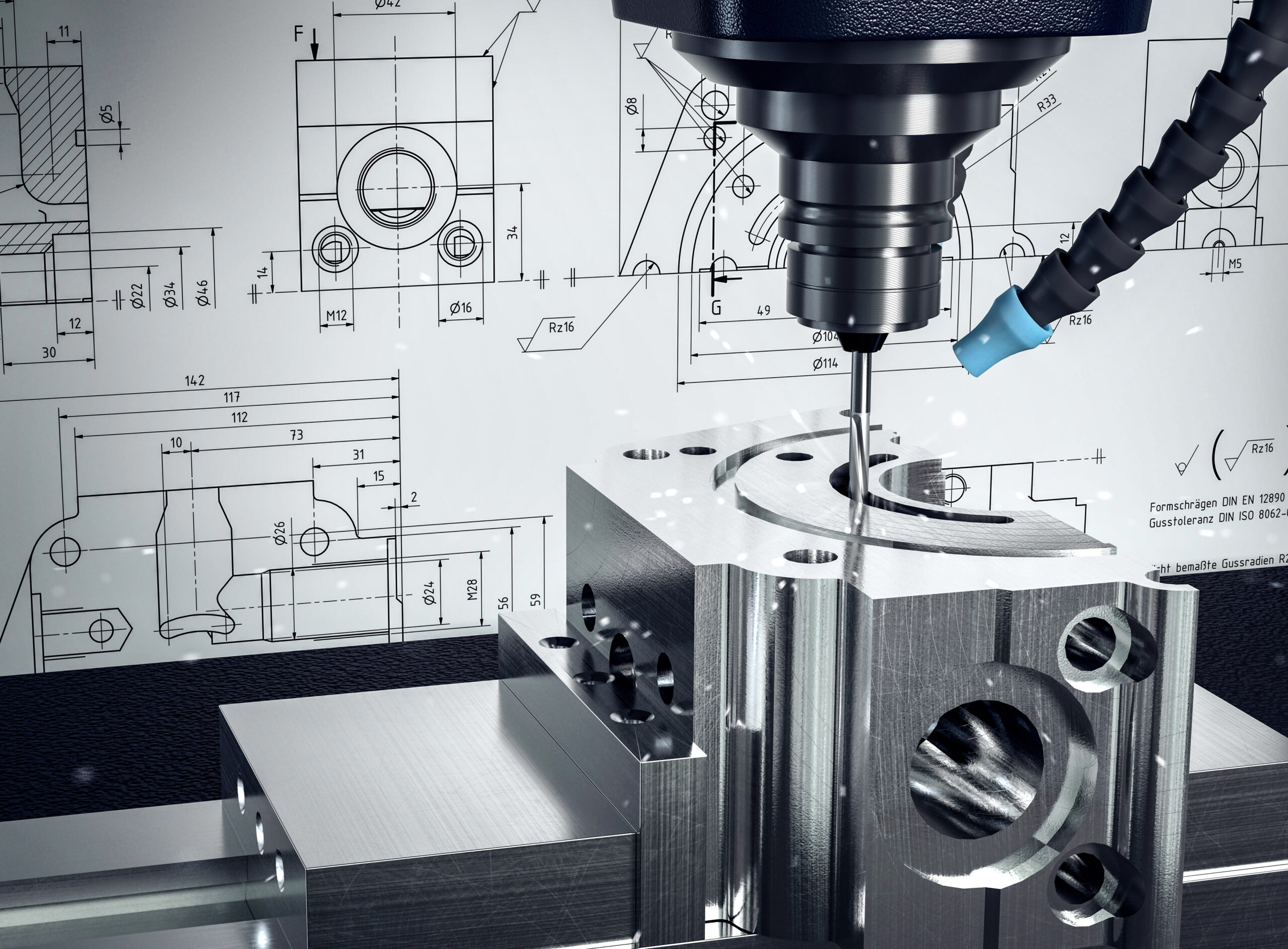

Precision Machining for Defense Applications

Beyond Complexity and Into Mission-Critical Performance When it comes to aerospace, clean energy, or industrial equipment, precision always matters. But in precision machining for defense applications, precision becomes mission-critical. A single component that’s out of tolerance can compromise system performance or shorten equipment life. For defense contractors, reliability isn’t just a requirement, it’s a responsibility. […]