Inspection and Reports

We provide precise dimensional reports to ensure accuracy and quality for every part.

FAI, SPC, PPAP, FMEA, and More…

Quality, precision, and compliance are at the core of our Comprehensive Inspection & Reporting Services. We ensure every component meets the highest industry standards through rigorous testing and data-driven analysis, guaranteeing accuracy from prototype to production. We utilize state-of-the-art measuring devices to produce detailed reports, ensuring your parts meet exact specifications.

Why Choose Us?

- First Article Inspection (FAI) – Verifying part accuracy before full production.

- Statistical Process Control (SPC) – Data-driven quality monitoring.

- Production Part Approval Process (PPAP) – Ensuring manufacturing consistency.

- Failure Modes and Effects Analysis (FMEA) – Identifying and mitigating risks

- Complete Dimensional Analysis – Full inspection of all critical features

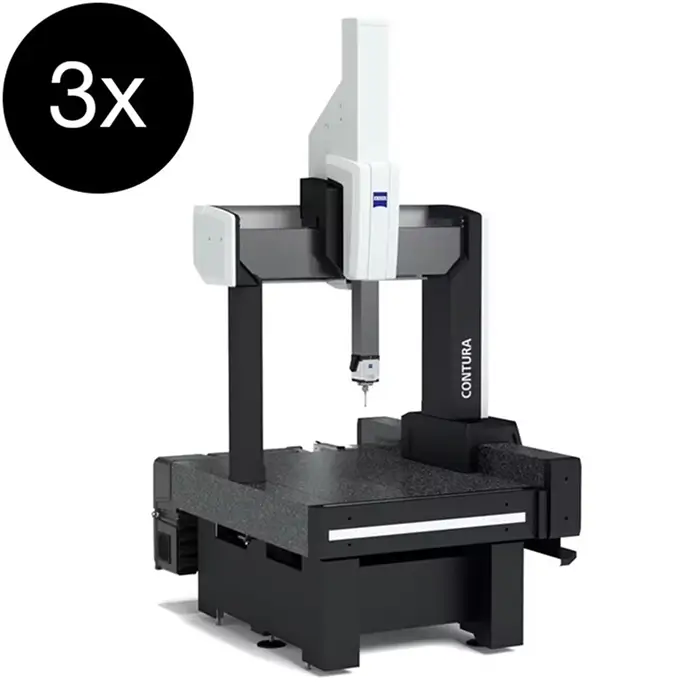

Equipment

Carl Zeiss CMM

Contura G2 RDS/XXT 10126

(1000mm x 1200mm x 800mm)

Contura RDS/XXT 7106

(700mm x 1000mm x 600mm)

Contura RDS/XXT 9128

(900mm x 1200mm x 800mm)

Precision up to 1.7 + L/350 (µm)

CMM Optique Mituoyo

MITUTOYO QV APEX 302 pro

300 x 200 x 200 (mm)

Expansion up to 960x

Precision up to 1.5 + L/1000 (µm)

FAQS

Can you inspect parts that were manufactured elsewhere?

Yes! We provide independent dimensional reports for any parts, regardless of the manufacturer.

What inspection equipment do you use?

We use high-precision tools such as CMMs (Coordinate Measuring Machines), laser scanners, and other advanced metrology instruments.

What industries do you provide inspection services for?

We serve aerospace, medical, defense, robotics, and other high-precision industries requiring strict quality control.

Do you provide compliance documentation?

Yes, we offer full compliance reports, including AS9102 FAI reports and other industry-standard documentation.

How long does an inspection typically take?

Turnaround times vary based on part complexity, but we prioritize efficiency while maintaining the highest accuracy.

Ready to Get Started?

Ensure precision and compliance with our advanced inspection services.