In precision manufacturing, quality cannot be validated by appearance alone. Components must be measured, documented, and verified against exact standards to ensure performance and safety. This is where precision machining inspection and reporting services play a critical role.

These services provide dimensional verification, process validation, and full traceability ensuring each part meets customer, industry, and regulatory requirements.

Why Inspection Is Essential in Precision Machining

High-reliability industries such as aerospace, defense, and medical manufacturing rely on documented inspection to:

- Confirm parts meet drawing tolerances

- Validate manufacturing processes before production scaling

- Maintain compliance with standards such as AS9102 and ISO 9001

- Provide evidence for audits and customer approvals

Without a structured inspection process, even minor deviations can result in part failure, delays, or program risk.

Key Inspection and Reporting Methods

Megatech provides a full range of precision machining inspection and reporting services, including:

- First Article Inspection (FAI / AS9102): Establishes baseline conformity before production begins.

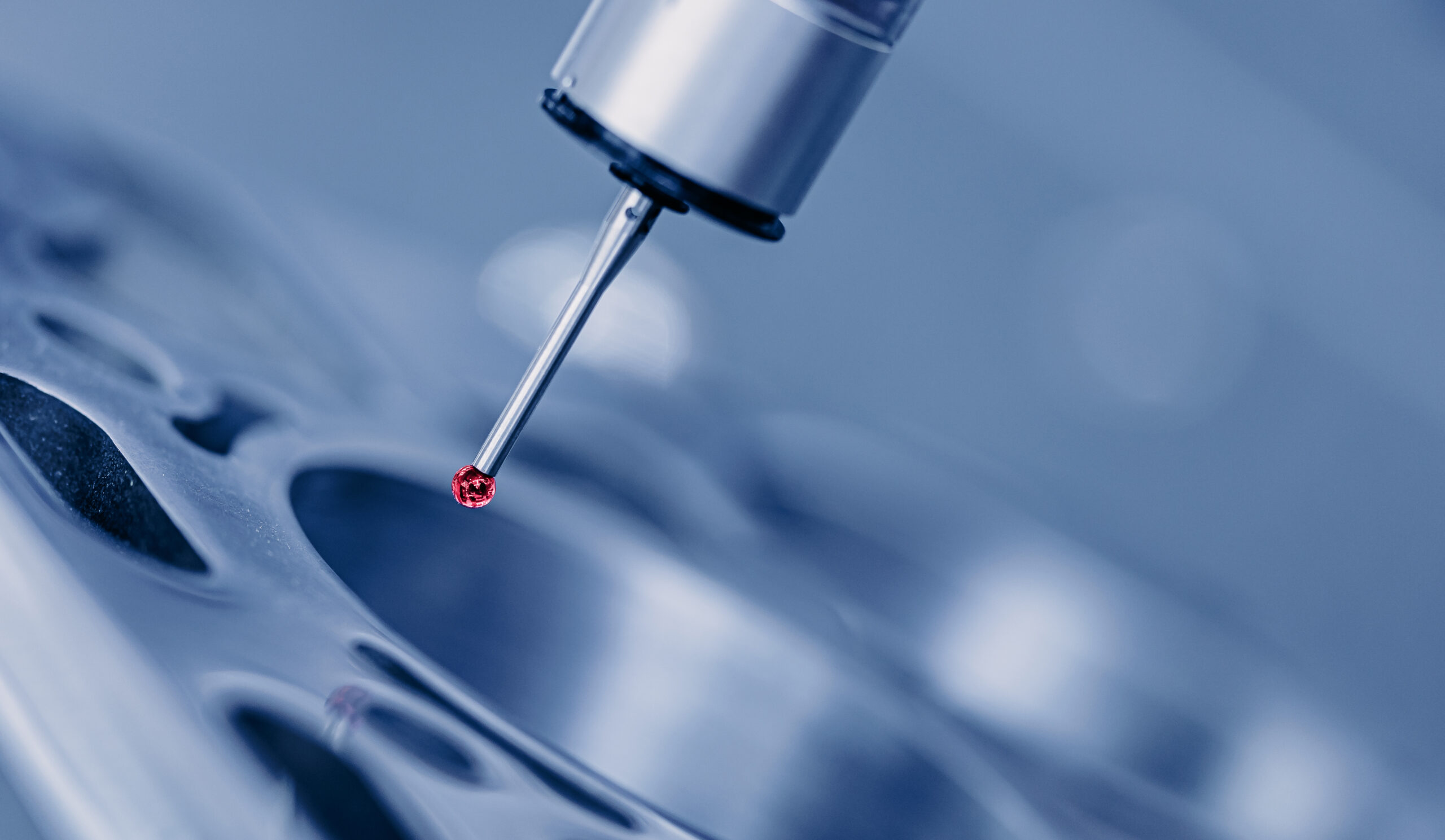

- Coordinate Measuring Machine (CMM) inspection: Enables micron-level measurement of complex geometries.

- Production Part Approval Process (PPAP): Confirms that repeat production will consistently meet specifications.

- Statistical Process Control (SPC): Monitors process variation to prevent nonconformance.

- Dimensional and material reporting: Provides full documentation for traceability and performance verification.

These reports are not optional add-ons; they are fundamental tools for quality control and risk mitigation in advanced manufacturing.

How Inspection Data Supports Better Manufacturing Outcomes

Inspection reports don’t just confirm quality, they improve it. By analyzing inspection data, engineers can identify trends, optimize machining strategies, and reduce variability over time. This creates a closed-loop quality system where inspection informs continuous improvement.

Conclusion

Precision machining inspection and reporting services are essential to ensuring part reliability, regulatory compliance, and manufacturing consistency. For OEMs and suppliers working in high-stakes industries, these processes are an integral part of delivering qualified, production-ready components, not an afterthought.

Because when accuracy defines success, every micron counts.

Contact us HERE.

Follow us on LinkedIn HERE.